Superior Edge Retention

Hock Blades hold their sharpness longer than standard tools, reducing downtime for sharpening and keeping your work flowing smoothly.

Quality Manufacturing

Each blade is made to exact specifications, ensuring consistent performance and perfect fit with your tools every time.

Durable Construction

Built from high-quality steel that stands up to heavy use, these blades maintain their integrity through countless projects.

Choose Your Blades and Tools

Match the blade to your plane type and the wood you’re working—thicker irons reduce chatter on figured hardwoods while standard thickness works fine for softwoods and general planing. Check the width, bevel angle, and whether you need a chip breaker, then pick steel that suits how often you want to sharpen versus how long you need the edge to last.

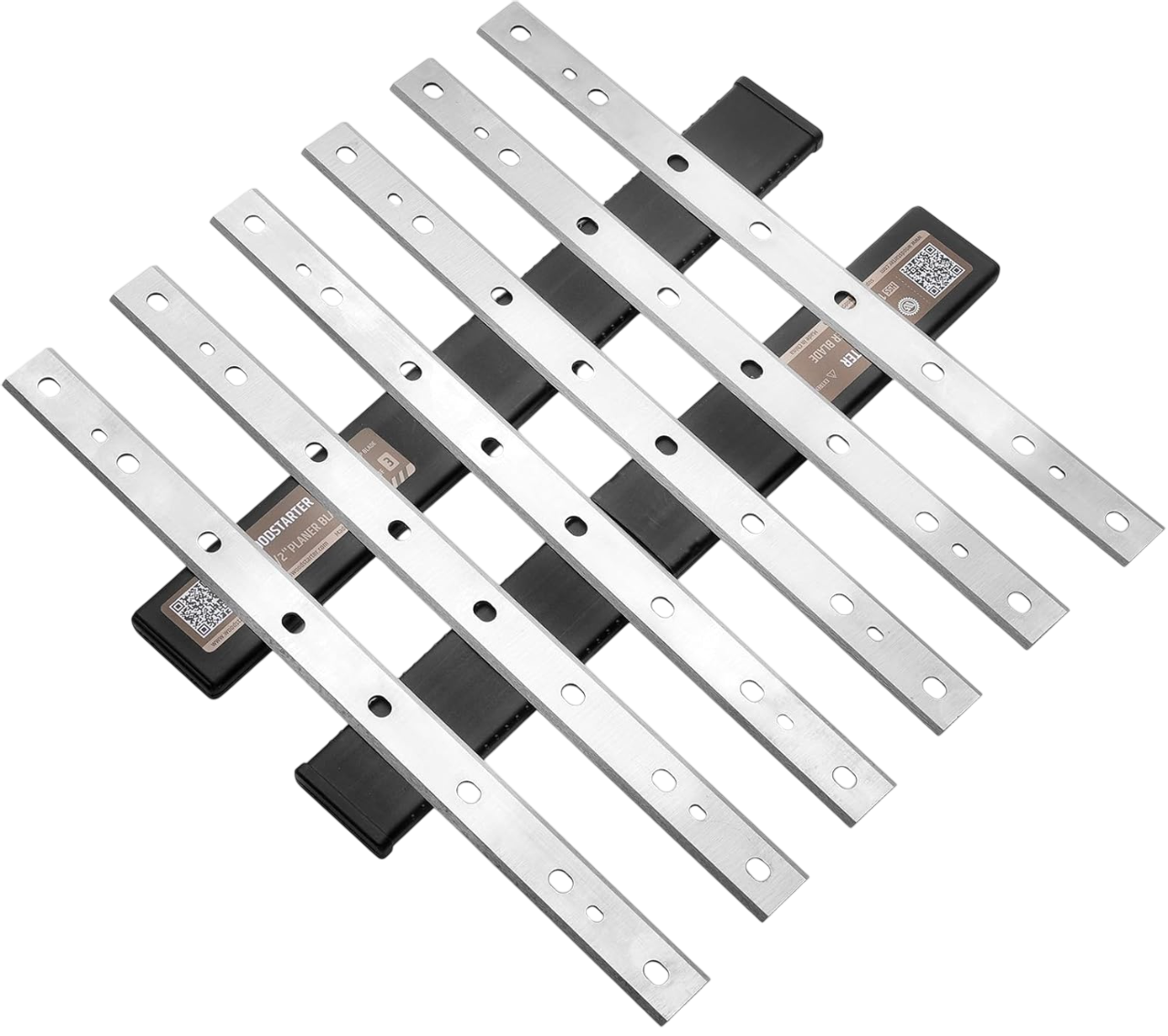

6pcs 12-1/2 Inch Planer Blades for Dewalt DW734 Planer

This 6-piece set of 12.5-inch HSS blades fits DeWalt DW734 planers with dual cutting edges that can be flipped when one side dulls, extending usable life before needing replacement or resharpening.

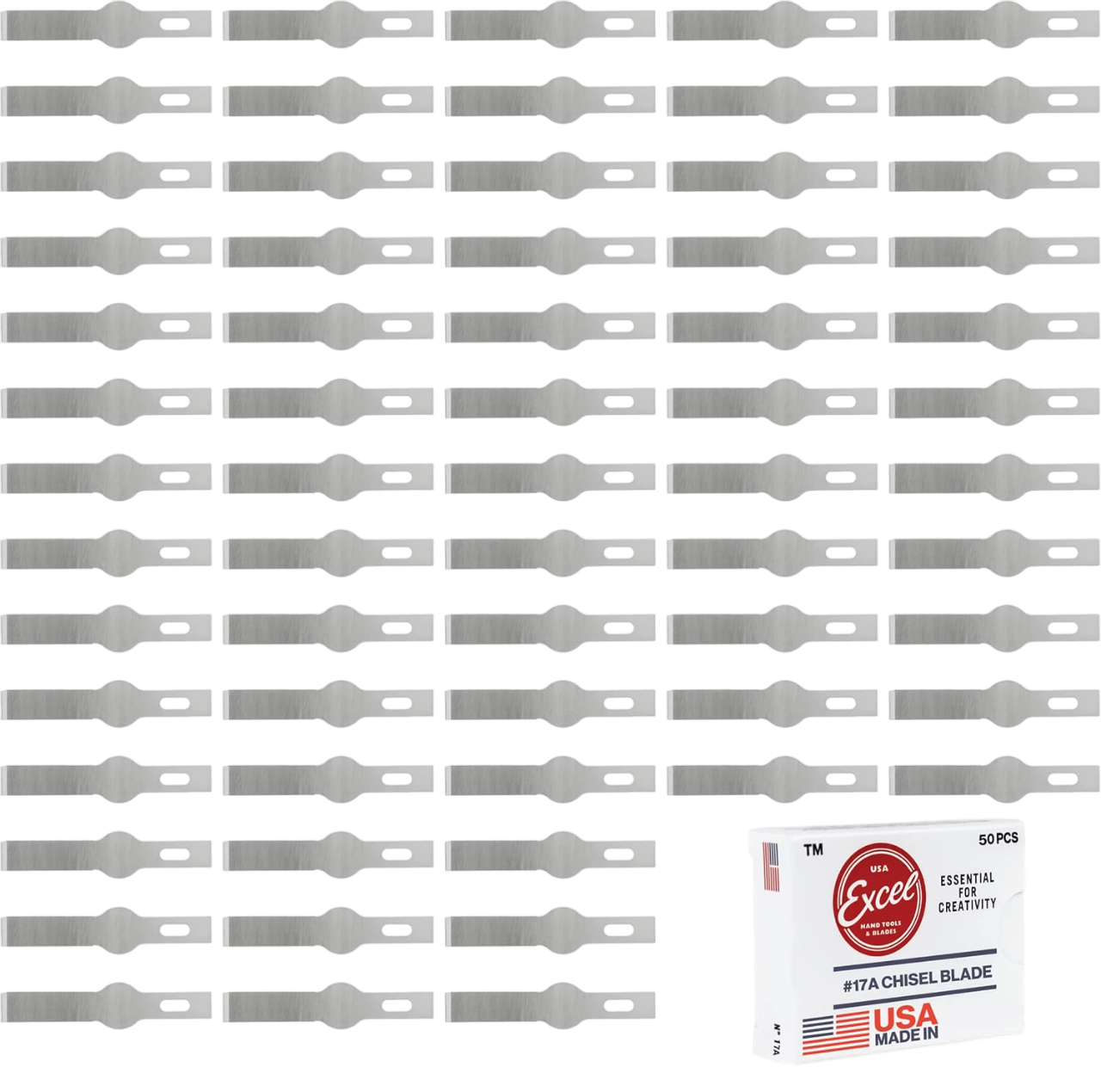

Chisel Replacement Blades – 50 Pack

These 50 USA-made #17 chisel blades feature double-honed edges for precise trimming and cutting of wood, plastic, paper, and leather in craft and hobby projects.

3-Hole Blades Film Slitting Blade 100 Pcs Replacement Blades

This 100-pack of 3-hole slitting blades fits film and vinyl cutters, providing sharp replacement edges for cleanly cutting backing paper and thin materials without tearing.

Chisel Replacement Blades – 50 Pack Carbon Steel Blades

This 50-pack of USA-made carbon steel #17 chisel blades provides sharp, durable edges for precision carving and trimming across various craft and hobby applications.

V3 Replacement Blade For No. 4/No. 5 Bench Plane

This replacement blade fits Woodriver V3 No. 4 and No. 5 bench planes, restoring sharp cutting performance when the original blade becomes worn or damaged beyond resharpening.

Blades #18 Wood Chisel Blades

These 50 USA-made 1/2-inch wood chisel blades fit Excel K2, K5, and K6 handles with high carbon steel edges designed for carving, shaving, and detail work in wood and other materials.

2pcs Adjustable SpokeShave with Flat Base

This set includes two adjustable flat-base spokeshaves with six metal replacement blades for shaping curved and contoured surfaces in woodworking and carving projects.

2pcs 9″ 10″ Adjustable Spokeshave with Flat Base

This kit includes 9-inch and 10-inch adjustable spokeshaves with four replacement blades and a 4-way rasp file for shaping, trimming, and smoothing wood surfaces and edges.

467177 Replacement Blade/Iron

This 2-1/8-inch wide replacement blade fits Taytools spokeshaves with 0.070-inch thickness and RC 55-60 hardness for reliable edge retention during shaping and smoothing work.

subscribe to newsletter

About Brand

Hock Tools started in 1981 when Ron Hock decided woodworkers deserved better plane irons than what was coming stock in most hand planes. He focused on making replacement blades from quality steel that would actually hold an edge through a full day of work, not dull out after a few passes on hard maple.

The plane irons are made from high-carbon tool steel, properly heat-treated to the right hardness for edge retention without becoming so brittle they chip when you hit a knot. Hock offers different thicknesses—standard weight for most work and thicker versions that reduce chatter in older planes or when working difficult grain. The extra mass helps the blade cut smoothly through figured wood that would otherwise tear out with a thin, flexy iron.

Hock makes blades for just about every common plane out there—Stanley and Record bench planes, block planes, shoulder planes, and specialty tools. The dimensions are precise so they fit properly without sloppy side-to-side play or binding in the mouth. You’re not filing and fitting for an hour just to get the blade seated right.

The chip breakers that pair with Hock irons are engineered to actually break chips instead of just sitting there looking important. Proper contact between the chip breaker and blade face prevents tearout on reversing grain and gives you cleaner cuts on tricky woods. The fit matters here—cheap chip breakers leave gaps that let shavings jam underneath and ruin the cut.

What separates Hock blades from factory irons is the steel quality and heat treatment. These blades take a finer edge because the steel is uniform without inclusions or soft spots. They hold that edge longer because the hardness is dialed in correctly. When you do need to sharpen, the steel responds well—it doesn’t take forever to grind a new bevel and the edge doesn’t crumble when you’re honing.

Woodworkers who’ve upgraded to Hock blades talk about the difference immediately. Planes that struggled through hardwoods suddenly glide. Tearout problems disappear. Sharpening intervals stretch from every twenty minutes to a couple hours of actual work. The tools feel different in hand because they’re cutting cleanly instead of fighting the wood.

Ron Hock also wrote “The Perfect Edge,” a book on sharpening that’s become required reading for hand tool woodworkers. The guy knows edges—how to form them, how to maintain them, and what steel properties matter for different cutting tasks. That knowledge went directly into designing his blades.

Hock Tools is small-scale manufacturing done right. They’re not stamping out thousands of blades per hour in some overseas factory. The focus stays on quality steel, proper heat treatment, and accurate dimensions. For woodworkers who rely on hand planes for joinery, smoothing, and detail work, Hock blades turn decent planes into tools that perform the way the old craftsmen’s planes did before mass production cheapened everything. You pay more than a hardware store replacement blade, but you get steel that actually works.

FAQ

Hock Blades use higher quality steel and are heat-treated to achieve better hardness. They hold their edge longer and take a sharper edge than most factory blades.

Hock makes replacement blades for most Stanley, Record, and other common plane brands. Check the product specifications or contact them with your plane model to confirm compatibility.

Some thicker blades may require minor adjustments like filing the mouth opening or adjusting the chipbreaker. Most planes can accommodate the change without major modifications.

Frequency depends on the wood type and amount of use, but Hock blades typically stay sharp 3-5 times longer than standard factory blades.

A2 steel is harder and holds an edge longer but takes more effort to sharpen. O1 steel sharpens easily and gets very sharp but may need touching up more often.

Yes, unused blades can be returned within 30 days. Make sure to check measurements before installation.

Ask your question

clients thought

Woodworkers consistently praise Hock blades for holding a sharp edge longer than standard blades, with many noting the difference is immediately noticeable in cleaner cuts and less frequent sharpening. The thicker construction gets mentioned often—people appreciate how it reduces chatter and vibration, making their planes perform more predictably on difficult grain.

I was skeptical about spending more on replacement blades, but after installing a Hock blade in my old Stanley No. 4, the difference was immediate. The shavings come off like silk ribbons now, and I can work for hours without needing to touch up the edge. It completely transformed a plane I was ready to retire.

Lisa Johnson

Customer

After 15 years of woodworking, I thought I knew what sharp meant until I tried a Hock blade. The first pass on a piece of cherry produced the thinnest, most consistent shavings I’d ever seen. My old blades seemed dull by comparison, even when freshly sharpened. It’s made my hand plane work so much more enjoyable.

Kevin O’Brien

Customer

I bought a Hock blade for my grandfather’s old plane that had been sitting in my garage for years. What a transformation! The blade cuts through hardwood like butter and leaves a finish so smooth I barely need to sand. It’s amazing how much better my weekend projects look now with just this one upgrade.

James Rodriguez

Customer